The module allows a fast and easy calculation of the geometry and strength of involute splines according to DIN 5480 (03/2006), DIN 5482 (03/1973), ISO 4156 (10/2005), ANSI B92.2M-1980 (R1989) and ANSI B92.1-1996. The geometry can be selected conveniently from a data base. The profile search function can help the user to quickly identify a profile. An own input of involute spline geometry is also possible.

Www.lmt-tools.com 21 rh1 relief ground khss -e speed core 20° α hss -pm al2 plus din 3968a din 3972 bp ii l2 l3 d1 d2 katalog-nr. 2033 m d1 l3 l1 d2 z ident no. 1 50 44 50 771 2 63 80 90 773 2,5 70 90 100 775 3 80 110 120 777 4 90 120 130 779 5 100 140 150 781 6 115 140 150. Description The module allows a fast and easy calculation of the geometry and strength of involute splines according to DIN 5480 (03/2006), DIN 5482 (03/1973), ISO 4156 (10/2005), ANSI B92.2M-1980 (R1989) and ANSI B92.1-1996. The geometry can be selected conveniently from a data base. Check out our Technical Gear Info page for data on diametrical pitch, involute splines, DIN 5480, DIN 5481, DIN 5482, DIN 5462, DIN 5463, and ANSI B92.1. 90 Bissel Street Joliet, IL 60432. Spline recent models grabcad cad library. Pss precision involute spline shaft ondrives. Din 5480 din 5482 gerardispa ru Din 5480 24 Spline Data PDF 1pdf.net Din 5480 24 Spline Data PDF. 10 Downloads 213 Views. Din 5480 Spline Data PDF - AvLib Din 5480 Spline Data PDF DIN 5480-1 Splined.

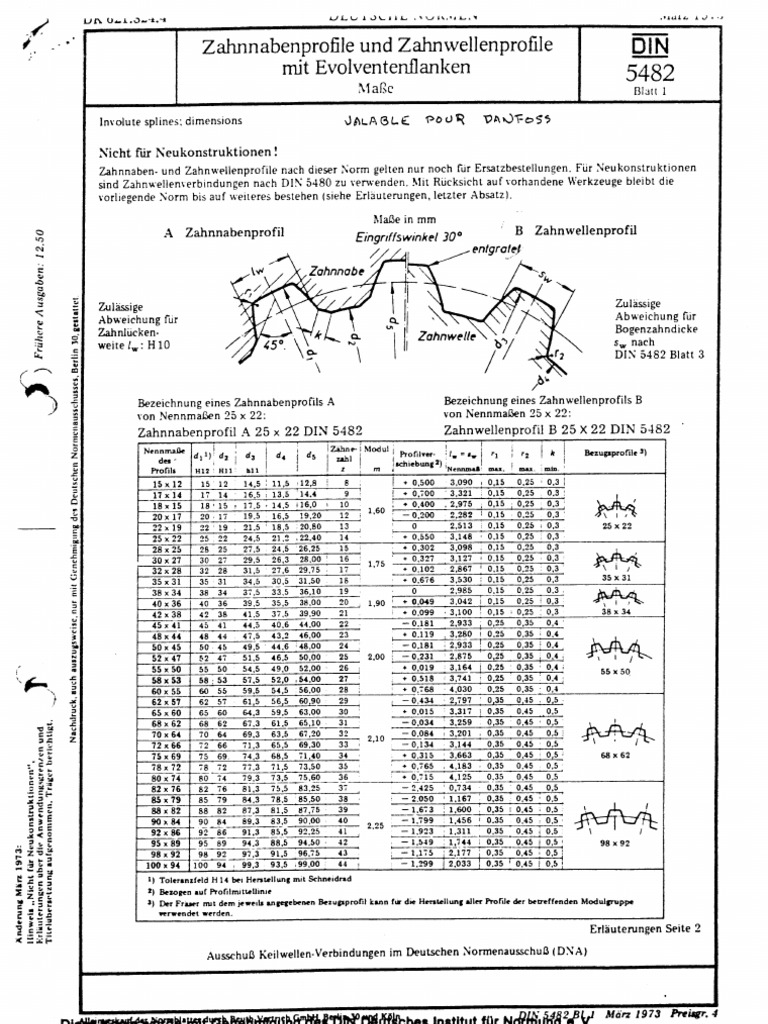

Imperial involute splines are to ANSI B92.1-1970 Class 5. On ANSI splines actual O.D. Of mating shaft may be smaller than shown as nominal spline O.D. To allow for root clearance. Metric involute splines listed are to DEUTSCHE NORMEN DIN 5480, DIN 5482 or DIN 5462.

The following tool types are available: hob, gear shaper cutter and constructed involute. Basic rack tooth profiles can be selected according to DIN 5480 for broaching, hobbing, shaping, cold rolling and diameter centering. Tool standard rack tooth profiles for the other standards are also available, e.g., for ISO 4156 30° flat root or 30° fillet root. All parameters for the basic rack tooth profile can be defined individually or determined automatically.

In order to determine the tolerances, the gear accuracy and backlash allowance sequence according to DIN 5480, DIN 5482, ANSI B92.2 and ANSI B92.1 can be selected from listboxes. This will determine the permissible deviations and tooth thickness allowances. The calculation of the tooth thickness allowances can be done based on measured values or given test dimensions. Test dimensions, backlash normal plane and backlash pitch diameter are calculated as well. For the test dimensions, the required number of the teeth for span measurement and the diameter of ball or pin will be determined automatically by the program or can be entered by the user.

Din 5482 Spline Data Pdf

The display of the accurate tooth form is a special highlight. The 2D DXF output is possible, the eAssistant CAD plugins allow to generate 3D models for different CAD systems. The tooth thickness is considered as well, so that the tooth form could then be used for manufacturing (e.g., milling, laser cutting, eroding).

The strength calculation is based on Niemann´s „Maschinenelemente“ Vol. 1, Edition 2001. The permissible surface pressures are determined from material properties, so it is possible to use special materials. Materials can be selected from the data base. For a different load input and output, the load factor according to DIN 6892 will be calculated based on the defined geometry. In addition, load peaks and alternating torque can be specified for the calculation. Dimensioning functions for the operation nominal torque, the maximum load peak torque and the supporting length help the user. The calculation results for the surface pressure and safeties for operation load and maximum load for shaft and hub are determined and displayed immediately during the input of values.

Din Spline Data

After the calculation is finished, a calculation report can be generated. The report includes the calculation method, all important input values and detailed results. The calculation report is available in HTML and PDF format.